UPDATE 28 OCT 2024:

We are sorry to say that this project has been placed on indefinite hold, so that Lou can attend to some family health matters. We thank you for your understanding, and wish Lou the best.

Summary

A new bioherbicide can replace atrazine by effectively targeting resistant weeds and offering safer environmental profiles. With atrazine’s market at $1.5B globally and broader applications for crops like soybeans and wheat, this novel bioherbicide presents a significant market opportunity. Producing it in yeast through precision fermentation is more suitable due to scalability and cost-efficiency, overcoming limitations of direct extraction from plants and enabling broader, commercial-scale availability for farmers.

To protect the invention and potential IP generation, the name of the naturally occurring bioherbicide has been redacted. To date, there’s no public documentation of anyone attempting to produce this compound in yeast, and thus there’s the opportunity for ValleyDAO and Cotyra to be the first movers in unlocking the bioproduction of this compound and securing the IP.

Team

Cotyra is a biotechnology development and consulting company located in Ithaca, NY near the Cornell University campus. The company focuses on developing new solutions in synthetic biology to address economic and environmental challenges of global importance.

The company was founded by Dr. Louis Hom, who over the last 15 years has led numerous programs to develop and commercialize a variety of bio-based products, including renewable chemicals/fuels, alternative food proteins, and nutraceuticals/active pharmaceutical ingredients. His prior experience includes managing the protein engineering, lab automation, and Next Generation Sequencing groups at Intrexon; overseeing strain development at ZeaChem, where he also managed the company’s partnership with Procter & Gamble; and serving as Vice President of R&D at Perfect Day Inc., where he established the company’s research program and patent portfolio. His experience and skills in industrial biotechnology span the full product development pipeline, from discovery to scaleup and commercialization.

Problem

Every year, American farmers spray >30 million kilograms of atrazine on their corn, sugarcane, and sorghum fields, making it the second most-used herbicide in the United States. Atrazine is also a well-known endocrine disruptor that presents a number of health and environmental hazards, which has led the Environmental Protection Agency (EPA) to propose new restrictions on its use.

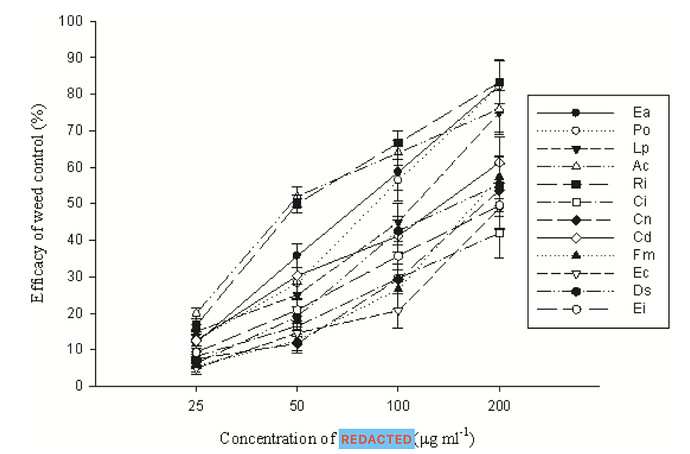

A promising alternative to atrazine has been identified from a naturally occurring compound that certain plants release through their roots to suppress competition from surrounding weeds. This compound has demonstrated potential as an effective weed control agent in greenhouse studies as outlined in the below figure and offers several significant advantages.

Influence of post-emergence application of varying concentrations of the bioherbicide candidate on common weed species control under field conditions. Data are shown as mean ± standard deviation (SD). Weed species abbreviations are as follows: Ea for Eclipta alba, Po for Portulaca oleracea, Lp for Ludwigia prostrata, Ac for Ammannia coccinea, Ri for Rorippa indica, Ci for Cyperus iria, Cn for Cyperus nipponicus, Cd for Cyperus difformis, Fm for Fimbristylis miliacea, Ec for Echinochloa crus-galli, Ds for Digitaria sanguinalis, and Ei for Eleusine indica.

-

Although it operates through a similar mechanism to some existing herbicides, it targets different binding sites, which allows it to be effective even against weeds that have developed resistance to those herbicides.

-

This compound can be used with a broader range of crops, providing greater flexibility for farmers.

-

It has lower mobility and breaks down more quickly in the soil compared to some commonly used herbicides, thereby posing a smaller risk to water supplies.

-

It helps reduce nutrient loss in the soil, thereby decreasing the need for fertilizer and associated costs. These combined benefits make it a highly attractive option for agricultural weed management.

However, its current availability is limited to root extracts of the plant that produces it, making it impractical for large-scale commercial use.

Solution

Precision fermentation has previously been demonstrated as a suitable technology for producing complex, high-value, biological compounds that are challenging or inefficient to synthesize through traditional chemical methods. This process leverages the natural metabolic pathways of organisms like bacteria or yeast and enhances them by integrating additional pathway enzymes through genetic engineering. This modification expands the organism’s capacity to produce a wider range of valuable compounds.

The genes and their associated enzymes required for biosynthesis of this bioherbicide candidate have been identified, and each of the encoded proteins has successfully been expressed in active form in microbial hosts. Researchers have previously attempted to engineer the pathway into a variety of crop plants, but failed to achieve secretion of the product. Cotyra will instead engineer the bioherbicide pathway into the yeast Saccharomyces cerevisiae to enable scalable, low-cost production via precision fermentation.

This solution will provide farmers with a valuable new tool in weed control, in the face of growing restrictions around atrazine and increasing resistance to herbicides in general. During customer discovery activities, Cotyra interviewed numerous Cooperative Extension agents (public university faculty and staff who work closely with farmers); and while they confirmed that there was an emerging need for an atrazine replacement, they also consistently pointed to the applications of this bioherbicide candidate in other crops like soybeans as potentially being an even bigger opportunity.

Market Opportunity

In 2022, global sales of herbicides totaled $31B, with $14B of that spent in North America. Although atrazine sales are substantial by themselves ($1.5B globally, $0.7B in North America), the serviceable addressable narket also includes herbicides used on other crops that can be protected with the bioherbicide, such as soybeans, wheat, barley, and tomatoes. Although the emerging new regulations around atrazine represent a key market driver, the rise of resistance and declining efficacy of other herbicides creates comparable opportunities around the other crops mentioned as well. Given the vast acreage involved, we believe that the serviceable obtainable market will be determined primarily by the achieved production capacity of the bioherbicide.

According to the University of Illinois, farmers currently spend about $111/ha for weed control, which typically covers 1-2 applications of herbicidal cocktails that each contain 2-3 different agents. Additionally, around $32 per hectare is spent on nitrogen stabilizers to minimize fertilizer loss due to microbial nitrification. Considering that early trials suggest an effective application rate of about 0.2 kg of the bioherbicide per hectare, a conservative estimate places the value at $170 per kg of the bioherbicide. According to Cotyra’s estimations a titer of around 15 g/L would be needed to break even at a fermentation scale of 250 m³.

Timeline & Budget

Throughout this 4 month project, Cotyra will build a proof-of-concept strain to demonstrate that the bioherbicide candidate can be produced in yeast.

Total funding amount is 50,000 and will be used for the following:

- $11,000 Lead Scientist

- $9,000 Molbio RA

- $6,000 Materials (enzymes, chemicals, labware)

- $4,000 Services (DNA synthesis, sequencing, etc.)

| Month | Objective | Budget($) | Payment Terms |

|---|---|---|---|

| 1-4 | 1. Construction of PoC yeast production host | 25,000 | To be paid upfront upon execution of the research funding agreement. |

| 1-4 | 2. Develop initial production assay to measure product concentration of the bioherbicide | 25,000 | To be paid upfront upon execution of the research funding agreement. |

Appendix

IP

There will be patenting opportunities for microbial production of the bioherbicide using the genes from its native producer plant, as well as engineered enzyme variants that are developed. Native plant sequences rarely function optimally in yeast, which creates an extensive IP opportunity for improved variants. Moreover, work with orthologs or other enzyme variants may also uncover more effective versions of the bioherbicide itself, bearing different quinone or side chain structures.

ValleyDAO will be the owner of resulting IP, and split proceeds from sub-licensing activities 50/50 with Cotyra. However, both parties agree that the optimal value capture opportunity is by spinning out a bioherbicide startup using the core IP. In the case of a spinout, ValleyDAO will receive 10% in equity as a co-founding stakeholder upon exclusively sub-licensing the IP to the spinout. ValleyDAO and Cotyra also retain the right to invest on the same terms as pre-seed investors, including participation rights under a Most Favored Nation clause. The parties may invest up to $250,000 each as operating capital in the startup through a SAFE note or similar investment instrument under the same terms as other pre-seed investors.

Senior Review Outcomes

Two senior reviewers were assigned this project and have been anonymized per request.

Reviewer 1, focusing primarily on the business fundamentals of the project, has an extensive background as a researcher, founder, business developer, and investor in biotech.

Reviewer 2, focusing primarily on the technical fundamentals of the project, has 10 years of experience working with yeast bioengineering.

Reviewer 1 comment:

The bioherbicide is positioned as both a complement to existing herbicides and a potential replacement for those facing resistance issues. Customer research conducted by Cotyra indicates that farmers are increasingly seeking alternatives due to resistance and regulatory constraints and are willing to invest in more effective solutions. The bioherbicide offers broad-spectrum effectiveness against resistant weeds while being compatible with crops sensitive to other herbicides, enhancing its versatility. Its persistence in soil is sufficient for crucial weed control periods without causing prolonged environmental impact. Additionally, its well-understood biosynthetic pathway provides a clear technical route for production, distinguishing it from other bioherbicides.However, some concerns remain regarding the uncertainty of developing adjacent products and the potential for higher initial costs, which could impact early adoption. More data is needed to confirm the bioherbicide’s effectiveness against all key target weeds in various agricultural settings. Despite these risks, the combination of a validated market need, clear customer interest, strong environmental benefits, and a feasible production strategy makes this project a compelling candidate for ValleyDAO funding.

Reviewer 2 comment:

The proposal to express the bioherbicide in yeast through precision fermentation presents a promising approach that addresses the challenges of previous plant-based expression systems, which failed primarily due to the inability to achieve secretion necessary for efficacy. The choice of yeast is well-justified given the ease of genetic engineering and availability of a broad toolkit, including CRISPR/Cas9 for genomic integration. The Cotyra team is well-prepared to manage potential bottlenecks and the complexities of expressing plant-derived enzymes, such as P450 proteins, through planned use of homologous enzymes, saturation mutagenesis, and fine-tuning of expression levels. They have access to the necessary analytical tools (HPLC and LC-MS) to identify and quantify both the bioherbicide and its intermediates, which is crucial for iterative strain optimization.However, there are risks to consider, particularly regarding the expression of a multi-gene pathway and the potential toxicity of the bioherbicide or its intermediates to yeast cells as titers increase. Cotyra has addressed these concerns by planning initial toxicity testing and suggesting strategies such as inducible expression and intracellular sequestration to mitigate these risks, demonstrating a well-thought-out and adaptable approach. While a few areas, such as the specifics of the modular cloning system and monitoring of protein localization, could benefit from further clarification, the overall plan is robust and grounded in sound scientific principles.

Risk Assessment

| Category | Comment | Risk | Risk Mitigation Plan |

|---|---|---|---|

| Business | The potential spinout from this IP would be a single-product entity, raising concerns about growth potential beyond the initial bioherbicide product. | Moderate | ValleyDAO, together with Cotyra and the future founding team, will work together in identifying product expansion candidates. The company will have a good market positioning, especially in the context of atrazine being banned in the EU, which would give it a strong competitive advantage using only the bioherbicide produced in this project while the company works towards identifying new product candidates to expand its agricultural product portfolio. |

| Tech | The individual enzymes haven’t been expressed collectively in yeast before. | High | This is by far the biggest risk of the project. According to research conducted by the ValleyDAO dealflow group, the enzymes have been independently expressed and shown activity across different organisms but have never been expressed collectively to form the metabolic pathway towards the bioherbicide. Introducing multi-enzyme pathways into yeast has previously been challenging due to folding requirements, proper post-translational modifications, compartmentalization, reaction rate limitations, metabolic burden/stress and genetic drift. Each of these risks can be mitigated through techniques which Cotyra has experience with like careful pathway optimization, protein engineering to ensure proper folding and functionality, compartmentalization strategies, optimizing enzyme ratios and expression levels to balance reaction rates, and implementing robust genetic constructs to prevent genetic drift over time. |

**

Low: Minimal risk that is well within ValleyDAO’s capacity to manage with existing resources. Requires little to no additional effort and poses negligible threat to project success.

Moderate: Significant risk that requires active management from ValleyDAO. While manageable, it would require a time investment from ValleyDAO to mitigate potential negative impacts on the project.

High: Critical risk with the potential to severely impact the project. Management of this risk may be beyond ValleyDAO’s control and could require significant intervention, resource commitment, or could ultimately lead to project failure if not addressed effectively.

Please vote below if the project should be approved for Snapshot voting where the community will pass a final vote using their GROW tokens

- Agree

- Disagree (comment is encouraged)

- Needs Revision (comment is mandatory)