From Microbes to Miracles - Unleashing the Future of Sustainable Oils and Fats

Summary

ValleyDAO has the opportunity to enter a sponsored research agreement (SRA) with Imperial College London. Led by Dr. Rodrigo Ledesma-Amaro, the project aims to engineer and generate novel strains that can efficiently produce and secrete fatty acids and lipid by-products. These lipids have the potential of replacing traditional petroleum and plant-oil based ingredients in industries such as food, fuels, cosmetics and biopharmaceuticals. ValleyDAO intends to use £228k from our treasury to fund this research project in exchange for an exclusive option to negotiate an exclusive license to the resulting IP.

Learn more about the project through our interview with Rodrigo:

Dealflow Team

- Scientific evaluation: Brian Sefton, Darren Nesbeth, Rebecca Vaught

- Business evaluation: Nicole Jackisch, Tuan Dinh, Alexandru Horghidan, Morgan Richards,

- IP evaluation: Daniel Hussey, Alexandre Maia

- Project management: Nicole Jackisch

- Shepherd: Albert Anis

- Sourced by: Max Mundt

- Project PI: Rodrigo Ledesma-Amaro

Problem

Lipids, which include fats (solid at room temperature) and oils (liquid at room temperature), are utilized in various industries such as cosmetics, biodiesel, food, and pharmaceuticals. However, the traditional methods of producing lipids, typically sourced from plants, animals or petroleum, have significant environmental consequences, such as deforestation, loss of biodiversity, harmful pesticide and fertilizer usage, extensive water and land consumption, and competition with food resources.

To address these concerns, scientists have been exploring synthetic biology production of lipids using microbes or yeast in bioreactors as a more sustainable alternative. Although this method holds promise for meeting the demand for lipids, its widespread adoption faces challenges, primarily due to high costs. A significant portion of these costs, up to 70% (1), is attributed to the downstream process of production, which involves separating the lipids/fats from other components of the microorganism. As a result, finding ways to reduce these costs is crucial for the broader implementation of this sustainable approach to lipid production.

Opportunity

The Research

Dr. Rodrigo Ledesma-Amaro has over a decade of synthetic biology and metabolic engineering experience. He’s currently leading a research group at Imperial College London (ICL) that has developed unique tools for working with lipid-producing yeast.

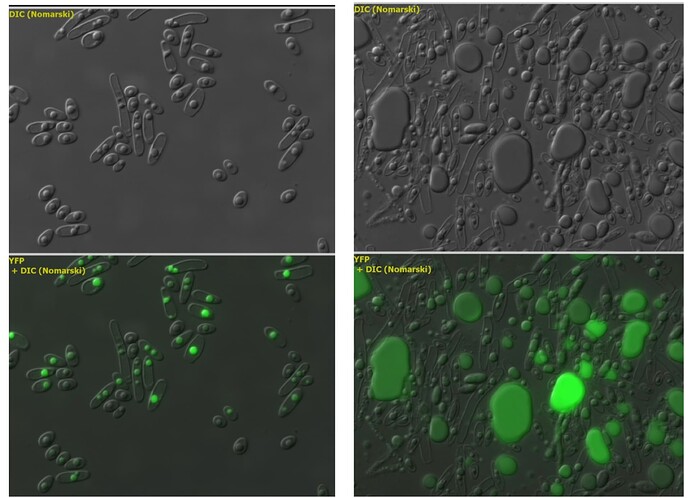

His lab has shown that it is technologically possible to engineer strains that both produce and secrete fatty acid and lipid by-products in high quantities (2), see figure below. This accomplishment can revolutionize biomanufacturing by significantly reducing production costs which would improve costs of goods sold in an industry that is known for its extremely tight margins (3).

Left image showcases wild-type yarrowia lipolytica strain. Right image showcases the same strain but engineered to produce and accumulate approximately 475 more extracellular lipids (2). The green lumps are lipids stained with Bodipy for microscopic analysis.

Collaboration

The ValleyDAO deal flow team has established a strong relationship with Dr. Ledesma-Amaro and ICL’s tech transfer office. The team has negotiated an SRA that grants exclusive negotiation rights to any resulting intellectual property (IP) emerging from the research funded by ValleyDAO.

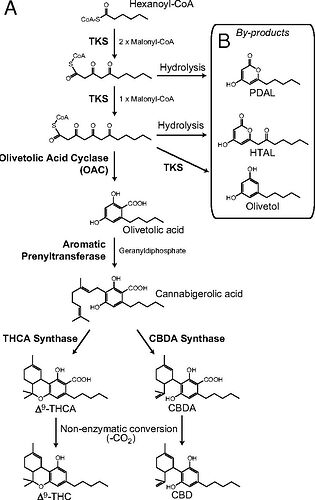

Commercialisation

The research project has the potential to generate IP with a broad range of applications in various markets. In the growing foods sector, there are significant opportunities to develop alternatives to plant oils (e.g palm oil and THC precursors), and animal-free products (e.g. omega-3, DHA & ARA) This creates potential for both venture creation and technology sublicensing, as biomanufacturing companies in these industries currently face high downstream processing costs which results in many companies having to cease operations. If Rodrigo’s project was to be successful, it could generate valuable IP applicable to a wide range of use cases and support in solving the cost-of-goods-sold bottleneck in the industry.

Cost & Milestones

The budget is £228,000 divided in 6 quarterly payments. Dr. Ledesma-Amaro has helped us in reducing the overhead costs to a minimum, an equivalent project to an established company would have cost ValleyDAO twice as much. Around 80% of the budget will go towards covering the salary (+social taxes) of a 2-year postdoc position with the remaining 20% going towards consumables and lab fees.

| Milestone | Description | Payment |

|---|---|---|

| Up-front-payment (month 0-12) | First payment will be paid up-front in order to achieve milestone 1 | £115,500 |

| 1 | One or more oleaginous yeast strains with improved production and secretion of fats and lipids | £89,750 |

| 2 | Development of confidential bioprocess and hand-in of final scientific report | £22,750 |

| Total | £228,000 |

IP Roadmap

- Exclusive License from Imperial College of London: SRA will provide an exclusive option to negotiate an exclusive license to resulting IP. We envision patentable oleaginous yeast strains and novel mutations that can be incorporated across different organisms, widening the IP potential even further.

- We expect to have Freedom to Operate and have taken steps to plan for development of strains that do not have third party rights or prior art.

- We envision to spin out the resulting IP through internal incubation within ValleyDAO and through partnerships with identified several collaborators with whom we’ve already initiated dialogue.

The diverse community supports research through interdisciplinary feedback and collaboration with respect towards bringing it to life outside the lab. Members with business backgrounds explore commercialization opportunities and foster connections with potential partners and investors. Importantly, ValleyDAO’s entrepreneurial community members are open to creating spin-off companies based on the IP, which is a significant advantage as many innovations fail to materialize due to a lack of dedicated teams.

Highlights

- ValleyDAO plans to fund a research project with Imperial College London, led by Dr. Rodrigo Ledesma-Amaro, focusing on engineering lipid-producing yeast strains, with a £228k budget.

- The project aims to address the environmental concerns associated with traditional lipid production methods by significantly improving yeast and bioreactor lipid production efficiency.

- Dr. Ledesma-Amaro’s lab has previously made significant strides in the potential reduction of biomanufacturing costs by engineering strains that efficiently produce and secrete fatty acids and lipid by-products.

- The anticipated IP, encompassing patentable yeast strains and novel mutations, is expected to have broad applications across various industries, potentially leading to venture creation and technology sublicensing.

- The diverse dealflow team at ValleyDAO, including scientific, business, IP experts, and project management, will collaborate with Rodrigo and ICL on future IP value capture and spinout creation.

Risk Assessment

| Risk | Comment/Mitigation Strategy |

|---|---|

| The bioengineering process may not generate the desired yeast strain with the capacity to produce and secrete fatty acids and lipids in higher quantities than previously reported. | Rodrigo has over a decade of experience working with oleaginous yeasts and has in the past successfully demonstrated numerous achievements of improved production of lipids using these organisms. |

| There may be existing patents that could block or restrict our freedom to operate, even with successful research outcomes | ValleyDAO will work closely with Rodrigo and the recruited postdoc during the project in ensuring that the goal IP is evaluated through prior art research. |

| The planned strategies may not lead to substantial cost reductions, despite successful strain development. | ValleyDAO, together with Rodrigo and the recruited postdoc, will conduct a comprehensive cost-benefit analysis at the onset of the project to clearly understand the various components of the cost structure. We will also identify suitable and high-value lipid targets that can compete with the pricing of existing lipids. |

Sources

(1) Grima et al, 2003. Recovery of microalgal biomass and metabolites: process options and economics. doi:10.1016/S0734-9750(02)00050-2

(2) Ledesma et al, 2016. Combining metabolic engineering and process optimization to improve production and secretion of fatty acids. Doi: 10.1016/j.ymben.2016.06.004

(3) Chatsko, 2022. How to Win in Synthetic Biology. https://ko-fi.com/post/How-to-Win-in-Synthetic-Biology-G2G8GQESL

- Agree

- Disagree (Comment is encouraged)

- Needs revision (Comment is mandatory)

0 voters